When it comes to structural steel in India, two widely recognized grades under the IS 2062 standard are E250 and E350. While both grades are reliable, the key difference lies in their strength, composition, and performance under load. Understanding the distinction between E250 vs E350 steel helps builders, engineers, and contractors make the right material choice.

1. Yield Strength and Load Capacity

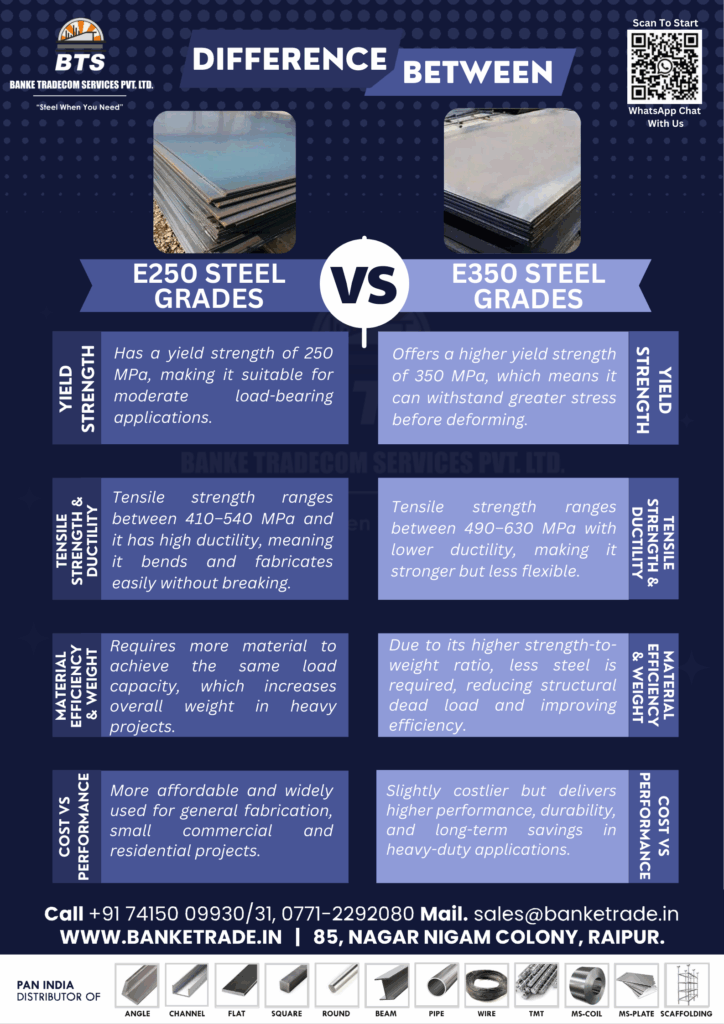

The biggest difference between E250 and E350 is yield strength—the point where steel starts to deform permanently.

- E250 Steel → Yield Strength of 250 MPa

- E350 Steel → Yield Strength of 350 MPa

👉 This means E350 is stronger and can handle higher stress without bending or breaking, while E250 offers better ductility and flexibility in fabrication.

2. Chemical Composition

Both grades follow IS 2062 guidelines but vary slightly in their alloying elements:

| Element | E250 Steel | E350 Steel |

|---|---|---|

| Carbon (Max) | 0.23% | 0.20% |

| Manganese | 1.50% | 1.55% |

| Sulphur (Max) | 0.045% | 0.040% |

| Phosphorus (Max) | 0.045% | 0.040% |

| Silicon | 0.40% | 0.45% |

🔹 Observation: Lower carbon in E350 improves weldability and toughness, while slightly higher silicon and manganese enhance strength and hardness.

3. Mechanical Properties

Mechanical performance sets the two grades apart:

| Property | E250 Steel | E350 Steel |

|---|---|---|

| Yield Strength | 250 MPa | 350 MPa |

| Tensile Strength | 410–540 MPa | 490–630 MPa |

| Elongation (%) | 23–26% | 20–22% |

| Hardness | Moderate | Higher |

| Impact Strength | Standard | Better at low temperatures |

👉 E250: More ductile and easier to bend, making it suitable for fabrication-heavy projects.

👉 E350: Higher tensile and yield strength, providing greater stability and load resistance.

4. Weight vs Strength Efficiency

- E250 is more flexible and forgiving in shaping and welding.

- E350, with its higher strength-to-weight ratio, ensures lighter structures can withstand heavier loads.

This makes E350 more efficient in projects where strength and material optimization are crucial.

5. Cost vs Performance Balance

- E250 Steel: Generally more economical due to lower strength requirements and easier fabrication.

- E350 Steel: Slightly higher in cost, but the added strength reduces the need for additional material in high-load structures, balancing the overall project expense.

Difference Between Steel Grade E250 vs E350

| Feature | E250 Steel | E350 Steel |

|---|---|---|

| IS Standard | IS 2062 | IS 2062 |

| Yield Strength | 250 MPa | 350 MPa |

| Tensile Strength | 410–540 MPa | 490–630 MPa |

| Ductility | Higher | Lower |

| Weldability | Excellent | Good |

| Hardness | Moderate | High |

| Fabrication | Easier to shape and bend | Requires careful handling |

| Weight Efficiency | Moderate | Higher strength-to-weight ratio |

| Fatigue Resistance | Standard | Stronger under cyclic loads |

| Impact Resistance | Regular | Superior, even at low temperatures |

Conclusion

The choice between E250 and E350 steel grades ultimately depends on the required balance of strength, ductility, and cost efficiency.

- E250 is more ductile and weldable, best suited for projects where fabrication ease is a priority.

- E350 offers higher strength and better performance under heavy loads, making it ideal for demanding structures.

Both are reliable under IS 2062 standards, and knowing their differences ensures safer and smarter construction decisions.

About us-

At BTS, we stand out as the leading steel dealer all over India. Our decades of experience, in-depth industry knowledge, and customer-first approach make us the preferred choice for all your steel requirements of various brands like SAIL, Tata Steel, JSW, Jindal, JSPL, etc. We proudly deliver PAN India, ensuring timely and reliable supply wherever you are.

📞 Call us now to get a quote!

📍 Location: Raipur (CG)

📞 Phone: 07712292080 | 07415009930 | 07415009931

✉️ Email: sales@banketrade.in | steel@banketrade.in

🌐 Website: www.banketrade.in

Blog Site– https://blog.banketrade.in/

Stay Connected with Us on

Read More- How SAIL E250 and E350 Steel Grades Improve Structural Stability