Understanding the trade-offs between Hollow and Solid Section bar steel elements is essential when working on modern construction, fabrication, or infrastructure projects. At Banke Tradecom Service Pvt Ltd, a trusted steel supplier in Raipur CG, we guide our clients to choose the most efficient materials based on strength, cost, and design objectives.

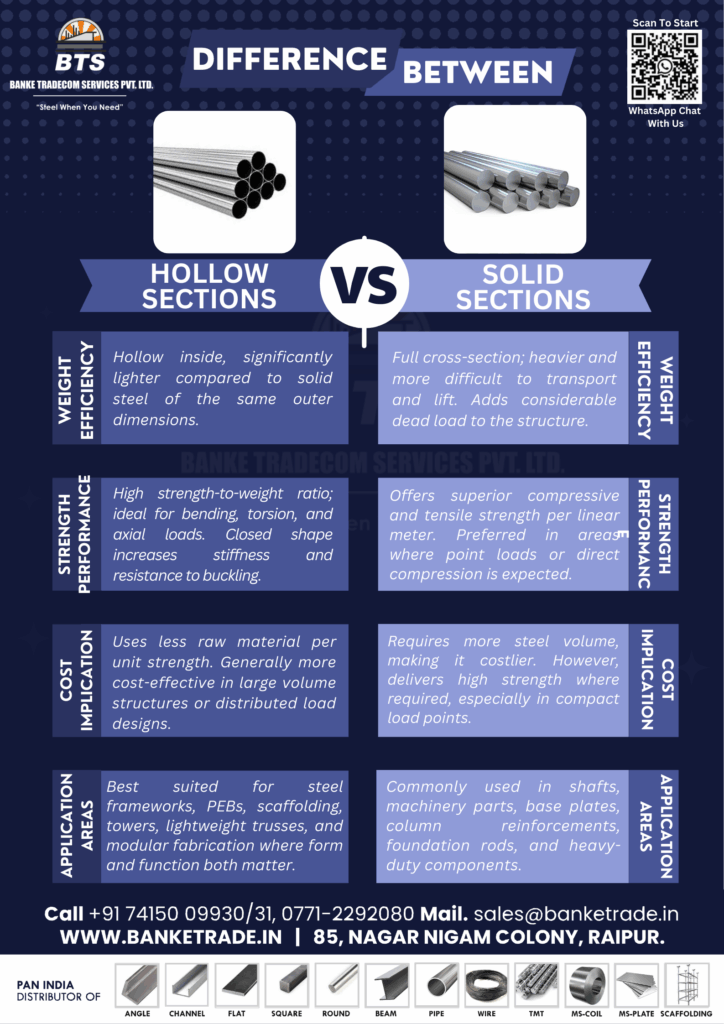

1. Structural Efficiency and Strength

Solid bars provide high compressive and tensile strength due to their full cross-sectional density. They are ideal for applications where maximum load capacity in a compact area is required.

Hollow sections, on the other hand, are designed to offer optimal strength with less weight. This makes them suitable for structures where load is distributed over a span, such as in trusses, frames, and columns.

Their shape (rectangular, square, or circular) helps resist torsional and buckling stresses, which adds to their design efficiency.

2. Weight Consideration and Material Optimization

One of the main advantages of hollow sections is their lighter weight compared to solid bars of the same external dimensions. This translates to:

- Easier transportation

- Reduced structural dead load

- Lower foundation requirements

- Faster erection time on site

When weight is a critical factor—such as in multistory buildings, pre-engineered structures, or mobile equipment—hollow sections provide a clear advantage.

3. Cost vs Performance Trade-Off

While solid bars may offer more strength per unit length, they are heavier and require more raw material, which increases procurement and handling costs.

Hollow sections, despite being lighter, often deliver comparable strength in load distribution, especially in axial or bending applications. This makes them cost-effective without compromising performance in many industrial and structural setups.

In large projects, choosing hollow sections can significantly reduce overall material costs, especially when sourced from a bulk steel supplier in India.

4. Fabrication and Design Flexibility

Hollow sections are easier to cut, weld, and fabricate into structural assemblies. Their closed profiles enhance both aesthetics and safety in public and commercial structures.

Solid bars, though robust, are less flexible in terms of design adaptability and are usually used in shafts, supports, machine components, and areas where impact strength is critical.

5. Application-Based Decision Making

Choose solid Section bars for:

- Heavy-duty machinery

- Anchor bolts

- Foundation reinforcements

- Static load points with minimal space

Choose hollow sections for:

- Steel frameworks

- Transmission towers

- Pre-engineered buildings

- Automotive and transportation components

Difference Between Hollow and Solid Section

| Feature | Hollow Sections | Solid Sections |

|---|---|---|

| Weight | Lightweight due to hollow structure | Heavier with full cross-section |

| Strength-to-Weight Ratio | High efficiency; ideal for distributed loads | High strength; better for point loads and confined spaces |

| Material Usage | Optimized – uses less steel for similar performance | Consumes more steel; increases material cost |

| Applications | Trusses, frames, transmission towers, PEBs | Shafts, foundation supports, heavy-duty components |

| Cost-Effectiveness | More economical in large, lightweight structures | Costlier due to higher weight and material volume |

| Fabrication & Welding | Easier to fabricate and integrate into modular designs | Requires more effort in fabrication and handling |

| Aesthetic Appeal | Clean, modern look; suitable for visible architectural use | Less aesthetic, often hidden in structural applications |

| Torsional Resistance | Excellent due to closed profile | Lower; may require additional support in torsional applications |

| Transportation | Easier and cheaper to transport | Requires more lifting and logistics effort |

| Design Flexibility | Versatile; supports multiple architectural and engineering needs | Less flexible; primarily used for load-bearing and static uses |

About us –

At BTS, we stand out as the leading steel dealer all over India. Our decades of experience, in-depth industry knowledge, and customer-first approach make us the preferred choice for all your steel requirements of various brands like SAIL, Tata Steel, JSW, Jindal, JSPL, etc. We proudly deliver PAN India, ensuring timely and reliable supply wherever you are.

📞 Call us now to get a quote!

📍 Location: Raipur (CG)

📞 Phone: 07712292080 | 07415009930 | 07415009931

✉️ Email: sales@banketrade.in | steel@banketrade.in

🌐 Website: www.banketrade.in

Blog Site– https://blog.banketrade.in/

Stay Connected with Us on

Read More👇