Introduction

Whether it’s for construction, maintenance, or inspections, scaffolding remains an essential component in modern infrastructure projects. As a leading steel supplier in Raipur CG, Banke Tradecom Services Pvt Ltd offers high-quality steel products essential for scaffolding, ensuring durability and safety in construction projects. This blog explores scaffolding’s significance, benefits, risks, and the rise of innovative alternatives like drones.

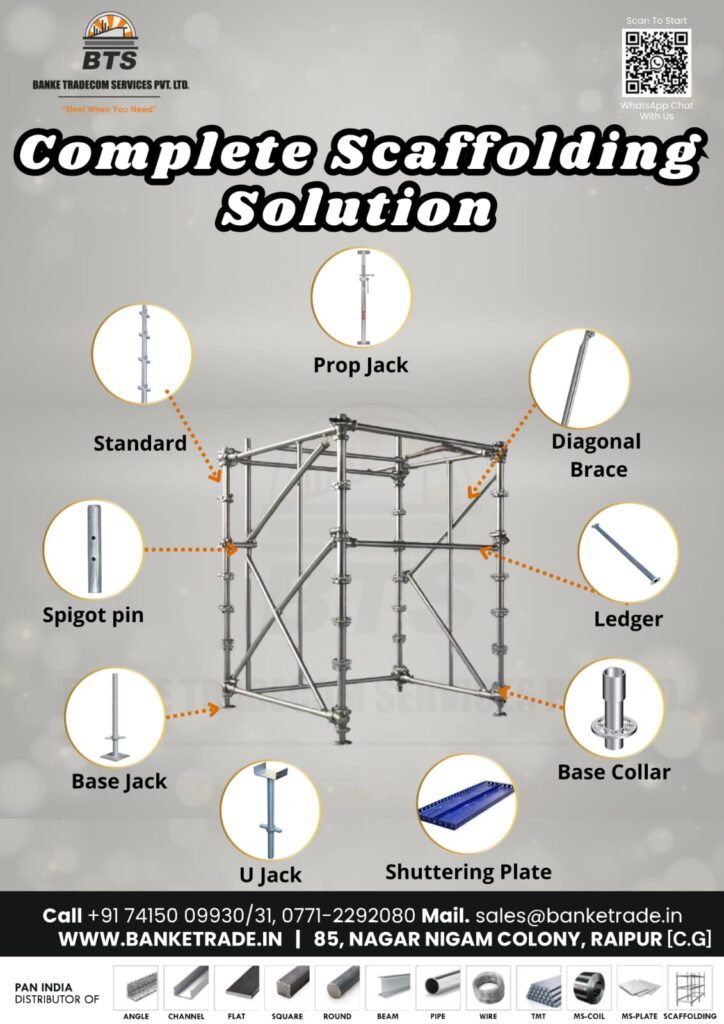

What Is Scaffolding?

Scaffolding, also called staging, is a temporary structure made of metal poles and planks that provides support for workers engaged in construction, maintenance, or inspections. It allows access to difficult-to-reach areas, ensuring efficiency and safety in various industrial applications.

Types of Scaffolding in Construction

Different types of scaffolding are used depending on project requirements. Here are the most common ones:

- Steel Scaffolding – Made from steel tubes, it is the most durable and widely used type, ensuring safety and stability.

- Suspended Scaffolding – Used for maintenance work like painting and window cleaning, it is suspended from the top of a structure.

- Cantilever Scaffolding – Used when there are obstructions on the ground that prevent the placement of standard scaffolds.

- Single and Double Scaffolding – Common in brick and stone masonry, with additional supports for better stability.

- Trestle Scaffolding – Portable scaffolding mounted on tripods, useful for light interior work.

Benefits of Scaffolding in Construction

Scaffolding remains a fundamental tool in construction due to its numerous advantages:

✔ Enhanced Access – Provides stable platforms for workers at high elevations.

✔ Better Balance – Ensures a secure footing, reducing risks of falling.

✔ Time Efficiency – Easy to assemble and dismantle, speeding up construction processes.

✔ Durability – Steel scaffolding lasts longer and withstands harsh environmental conditions.

✔ Safety – Minimizes fall hazards when properly installed.

✔ Bridging Function – Reduces unnecessary movement across job sites, improving productivity.

Dangers of Working on Scaffolding

Despite its benefits, scaffolding poses risks if not handled properly. Some common dangers include:

🔴 Structural Defects – Weak or compromised steel tubes and loose screws can lead to accidents.

🔴 Falling Objects – Unsecured tools or materials can cause severe injuries.

🔴 Weather Conditions – Rain, wind, or extreme temperatures can weaken scaffolding stability.

🔴 Poor Maintenance – Neglected scaffolding deteriorates over time, leading to structural failure.

🔴 Lack of Training – Workers without proper training are at higher risk of accidents.

Modern Alternatives:

With advancements in technology, drones are revolutionizing industrial inspections, offering a safer, faster, and cost-effective alternative to scaffolding. Traditional scaffolding requires time, labor, and high costs to set up, while drones can efficiently access hard-to-reach areas without putting workers at risk.

How Drones Are Changing Industrial Inspections

Drones equipped with high-resolution cameras, infrared sensors, and LiDAR technology can perform detailed inspections without the need for scaffolding. They can be used to inspect buildings, bridges, refineries, chimneys, boilers, wind turbines, and pipelines, providing real-time data for assessment and maintenance planning.

Key Benefits of Drone Inspections Over Scaffolding

✅ Improved Safety – Eliminates the need for workers to operate at height, reducing the risk of falls and injuries.

✅ Cost Savings – Avoids the high expenses of scaffolding setup and dismantling, cutting inspection costs by up to 80%.

✅ Faster Inspections – Drones can complete inspections in hours, whereas traditional scaffolding setups may take days or weeks.

✅ High-Quality Data Collection – Equipped with thermal imaging, 3D mapping, and AI analytics, drones provide accurate, detailed reports.

✅ Minimal Downtime – Unlike scaffolding, which may require shutting down operations for setup, drones allow businesses to continue operations while inspections are conducted.

✅ Versatile Applications – Drones can be used for visual inspections, structural assessments, corrosion detection, leak detection, and even hazardous material analysis in industries like construction, oil & gas, power plants, and infrastructure maintenance.

Why Companies Are Switching to Drones

Companies worldwide are replacing scaffolding-based inspections with drone technology to improve safety, efficiency, and cost-effectiveness. Industries such as power plants, refineries, chemical plants, and steel manufacturing have adopted drones to inspect confined spaces, detect defects, and monitor structural integrity without compromising worker safety.

While drones are a game-changer in industrial inspections, scaffolding still remains crucial for construction and repair work. At Banke Tradecom Services Pvt Ltd, the trusted steel supplier in Raipur CG, we provide high-quality steel pipes and scaffolding materials to ensure safety and durability in your projects.

About us-

At BTS, we stand out as the leading steel distributor all over India. Our decades of experience, in-depth industry knowledge, and customer-first approach make us the preferred choice for all your steel requirements of various brands like SAIL, Tata Steel, JSW, Jindal, JSPL, etc. We proudly deliver PAN India, ensuring timely and reliable supply wherever you are.

📞 Call us now to get a quote!

📍 Location: Raipur (CG)

📞Phone: 07712292080 | 07415009930 | 07415009931

✉️Email: sales@banketrade.in | steel@banketrade.in

🌐Website: www.banketrade.in 🌐Blog Site– https://blog.banketrade.in/

Stay Connected with Us on

Read More