When choosing steel pipes for construction, infrastructure, or industrial applications, understanding the types of pipe and differences between Electric Resistance Welded (ERW), Spiral Weld, and Seamless Pipes is essential. At Banke Tradecom Services Pvt Ltd, a trusted steel supplier in Raipur CG, we guide clients to select the right pipe type based on specific project requirements. Here’s everything you need to know.

Also Read- What Are MS Pipes? | Properties | Benefits | Applications | Top Manufacturers

To begin, let’s explore each type of pipe in detail, from how they’re manufactured to their primary uses and benefits.

1. ERW Pipes

Manufacturing Process

ERW Pipes, or Electric Resistance Welded Pipes, are created using low-carbon steel coils. Mild steel strips from these coils are rounded into tubes and passed through rollers to form a longitudinal seam, creating a welded joint along the pipe’s length.

Galvanized (GI) Pipes for Extra Protection

Some ERW pipes are available in galvanized form, known as GI pipes. These pipes are dipped in hot zinc for added rust resistance, which is essential for applications that involve water exposure, such as plumbing.

Applications

Sizes range from ½” (15nb) to 20” (500nb), making them suitable for various uses, such as:

- Firefighting systems

- HVAC and air conditioning lines

- Generators and plumbing lines

Advantages

- Cost-Effective Production: As ERW pipes are made from coils, they’re economical for standard applications, reducing project costs.

- Versatile Sizes: Available from ½” (15nb) to 20” (500nb), these pipes are versatile for various uses.

- Corrosion Resistance with Galvanization: When galvanized (GI pipes), they resist rust, ideal for applications involving water or moisture.

- High Brand Reliability: Banke Tradecom offers ERW pipes from trusted brands like JINDAL STAR and APL-APOLLO, ensuring consistent quality.

2. Spiral Weld Pipes

Manufacturing Process

Spiral Weld Pipes use HR steel coils that are unwound, flattened, and shaped into a cylinder with angled rollers, creating a distinctive spiral seam around the pipe. This process offers more flexibility for producing pipes with larger diameters and thicknesses.

Applications

Sizes range from 22” (550NB) to 64” (1600NB). Spiral Weld Pipes are ideal for large-scale projects, such as:

- Water transmission pipelines

- Oil and gas lines

- Infrastructure projects with large diameters

Advantages

- Large Diameter Range: Available from 22” (550NB) to 64” (1600NB), these pipes are suited for infrastructure requiring larger dimensions.

- Enhanced Flexibility: Spiral welding allows for variable thicknesses and diameters, making these pipes ideal for large-scale applications.

- Reliable Structural Strength: Their spiral seam offers good durability and stability, ideal for handling higher pressures.

- Tailored Production: Available on-demand, Banke Tradecom can supply custom specifications for unique project needs.

At Banke Tradecom Services Pvt Ltd, we source Spiral Weld Pipes from manufacturers like JCO Gas Pipe Ltd. and Steel Authority of India Ltd. Larger diameter pipes are available with extended lead times, as these are custom-produced upon order.

3. Seamless Pipes

Manufacturing Process

Seamless pipes are crafted without any seams, enhancing their strength and pressure capacity. There are two key production methods:

- Mandrel Mill Process: A solid steel billet is heated and pierced, followed by rollers that shape it to the desired diameter and thickness.

- Mannesmann Plug Mill Process: Similar to the mandrel mill process, this method allows multi-stage reductions to refine dimensions more precisely.

Applications

Due to their high-pressure capacity, seamless pipes are often chosen for critical applications, such as:

- Boilers and steam lines

- Oil and gas pipelines

- Industrial pressure lines

Seamless pipes generally have a 20% higher working pressure than welded options, though they come at a higher price.

Advantages

- High Pressure Capacity: With no seams, these pipes withstand approximately 20% more pressure than other welded pipes, suitable for critical industries.

- Uniformity: Without a welded seam, seamless pipes offer uniformity, ideal for applications needing flawless construction.

- Reliability under Temperature Variations: Seamless pipes perform well under high temperatures, making them suitable for extreme environments.

- Less Vulnerability to Corrosion: With no welded joint, they are less prone to corrosion and fatigue, adding durability.

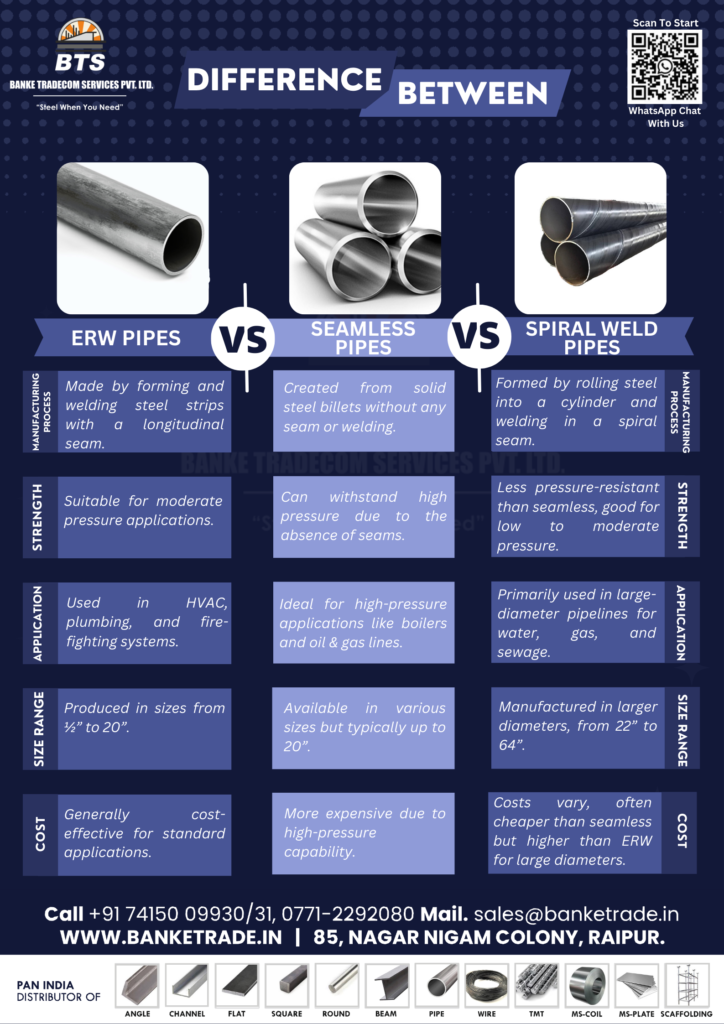

Comparison Table: ERW vs. Spiral Weld vs. Seamless Pipes

| Attribute | ERW Pipes | Spiral Weld Pipes | Seamless Pipes |

|---|---|---|---|

| Manufacturing Method | Low-carbon steel coils, welded longitudinally | HR steel coils, welded in a spiral | Heated billet, no weld seam |

| Size Range | ½” to 20” (15nb – 500nb) | 22” to 64” (550nb – 1600nb) | Variable, based on process |

| Pressure Capacity | Moderate | Moderate | High |

| Cost | Cost-effective | Moderate | Higher |

| Rust Resistance | With GI coating for extra resistance | Requires external coating | Naturally resistant due to solid form |

| Applications | Firefighting, HVAC, plumbing | Water transmission, large infrastructure | Boilers, oil & gas, high-pressure applications |

| Brands Offered | JINDAL STAR, APL-APOLLO | JCO Gas Pipe Ltd., Steel Authority of India | Custom, based on specifications |

Why Choose BTS?

At BTS, we stand out as the leading steel supplier in Maharashtra, Madhya Pradesh, Orissa, Punjab, Gujarat, Rajasthan, Chhattisgarh and all over India. Our decades of experience, in-depth industry knowledge, and customer-first approach make us the preferred choice for all your steel requirements of various brands like SAIL, Tata Steel, JSW, Jindal, JSPL, etc. We proudly deliver PAN India, ensuring timely and reliable supply wherever you are.

📞 Call us now to get a quote!

📍 Location: Raipur (CG)

📞Phone: 07712292080 | 07415009930 | 07415009931

✉️Email: sales@banketrade.in | steel@banketrade.in

🌐Website: www.banketrade.in 🌐Blog Site– https://blog.banketrade.in/

Stay Connected with Us on