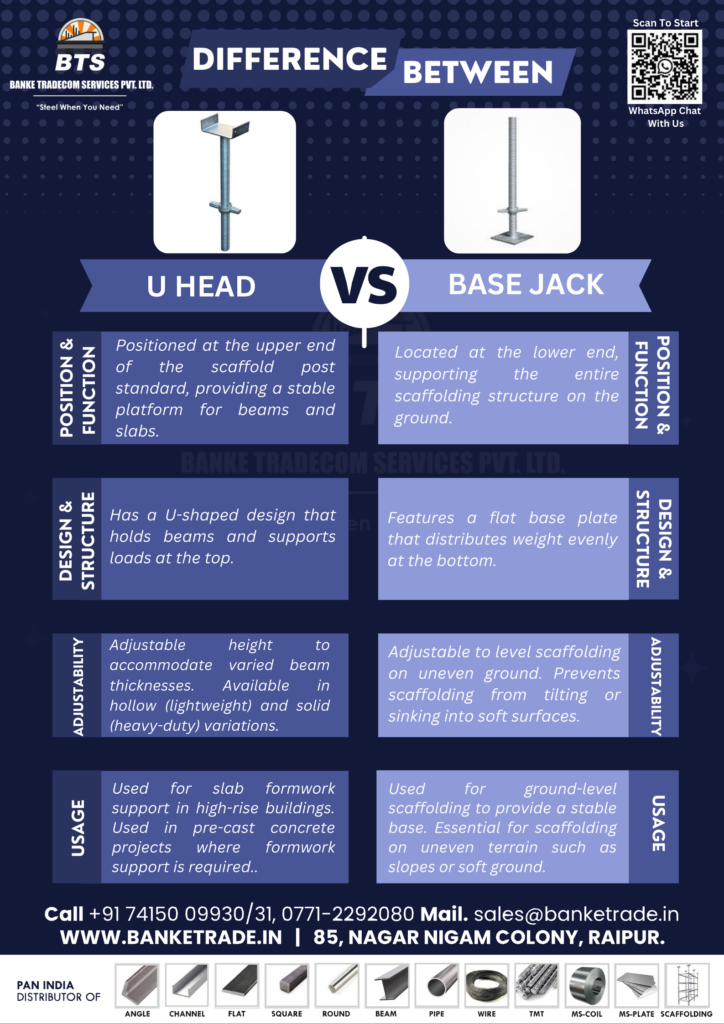

Among Scaffolding key components, U Head & Base Jack are vital for load-bearing and height adjustments. But what exactly sets them apart? Let’s explore their differences and classifications.

1. What is a U Head in Scaffolding?

A U Head (U Head Jack) is a top support component used in scaffolding systems to hold beams and formwork securely during construction.

Features:

✔ U-shaped design to support timber or steel beams.

✔ Comes with a threaded screw for height adjustments.

✔ Available in solid (heavy-duty) and hollow (lightweight) variations.

✔ Used in formwork systems for concrete pouring.

Uses of U Head:

✅ Provides stability to slabs, beams, and columns during construction.

✅ Helps in even load distribution from formwork to the scaffolding system.

✅ Commonly used in high-rise buildings, bridges, and tunnel formwork projects.

2. What is a Jack Base in Scaffolding?

A Jack Base (Base Jack) is a bottom support component that provides a stable foundation for scaffolding on uneven ground.

Features:

✔ Flat base plate for even weight distribution.

✔ Adjustable height with a screw mechanism.

✔ Made from solid round steel for durability.

✔ Used at the ground level of scaffolding.

Uses of Jack Base:

✅ Provides a stable base for scaffolding on uneven or soft surfaces.

✅ Prevents scaffolding from tilting or sinking.

✅ Essential in building construction, industrial scaffolding, and maintenance work.

Differences Between U Head & Base Jack

1. Function & Placement

- U Head:

- Positioned at the top of scaffolding.

- Designed to hold timber beams or steel formwork during concrete pouring.

- Distributes vertical loads efficiently.

- Jack Base:

- Positioned at the bottom of scaffolding.

- Acts as a foundation to keep the entire scaffolding structure stable.

- Helps distribute the load onto the ground.

2. Design & Structure

- U Head:

- U-shaped design for holding H-beams, timber planks, or steel beams securely.

- Available in fixed or adjustable types.

- Typically has a base plate and a threaded screw for height adjustment.

- Jack Base:

- Features a flat base plate with a threaded screw for height adjustment.

- Provides stability to scaffolding when placed on uneven or soft ground.

- Can be reinforced with a wooden plank or steel plate for extra support.

3. Adjustability

- U Head:

- The threaded screw allows for height adjustments based on beam thickness.

- Available in hollow (lightweight) and solid (heavy-duty) variations.

- Helps adjust the elevation of formwork to ensure proper leveling.

- Jack Base:

- The adjustable base plate allows scaffolding to be leveled on uneven terrain.

- Supports different scaffold heights and weight-bearing capacities.

- Prevents scaffolding from tilting or sinking into soft surfaces.

4. Load-Bearing Capacity

- U Head:

- Designed to support heavy loads from slabs, beams, and columns.

- Distributes vertical forces from above evenly to the scaffolding system.

- Essential for formwork stability in high-rise construction.

- Jack Base:

- Bears the entire load of the scaffolding system and transfers it to the ground.

- Helps prevent scaffolding collapse by evenly distributing weight.

- Made from heavy-duty steel to handle extreme loads.

5. Material & Construction

- U Head:

- Typically made of steel for strength and durability.

- Available in hot-rolled (stronger, higher cost) and cold-rolled (cheaper, less durable) versions.

- Comes in solid (higher load-bearing) and hollow (lighter weight) options.

- Jack Base:

- Made from solid round steel bars for maximum stability.

- Designed with anti-corrosion coating to resist rust.

- Can be welded or bolted to the scaffold structure for added security.

6. Usage in Construction

- U Head:

- Primarily used in high-rise buildings for slab formwork support.

- Essential in bridge construction, tunnel formwork, and beam support systems.

- Used in pre-cast concrete projects where formwork support is required.

- Jack Base:

- Used at the base of scaffolding to provide a stable foundation.

- Essential for scaffolding on uneven terrain such as slopes or soft ground.

- Commonly used in building exteriors, maintenance work, and industrial projects.

7. Stability & Safety Features

- U Head:

- Ensures firm positioning of beams to prevent shifting during construction.

- Adjustable lock system prevents accidental movement of supported formwork.

- Helps maintain alignment and load distribution in scaffolding.

- Jack Base:

- Provides firm ground contact to avoid scaffold tilting or sinking.

- Can be placed on a wooden board or steel plate to enhance stability.

- Prevents scaffolding from swaying due to uneven weight distribution.

8. Cost & Availability

- U Head:

- Slightly more expensive due to precision design and additional structural support.

- Price varies based on size, thickness, and type of steel used.

- More commonly used in large-scale projects that involve concrete formwork.

- Jack Base:

- Generally cheaper compared to U Heads, as it’s simpler in design.

- Readily available in standardized sizes.

- Widely used across various scaffolding systems, making it a cost-effective choice.

Classification of U Head & Base Jack

1. By Material Type

- Hollow Top Support: Made from thick-walled steel pipes, making it lightweight and easy to handle.

- Solid Top Support: Constructed from round steel, providing extra strength but is heavier.

2. By Manufacturing Process

- Hot-Rolled Screws: Feature a smooth and polished appearance with a slightly higher cost.

- Cold-Rolled Screws: More affordable but have a less refined finish compared to hot-rolled screws.

About us

At BTS, we stand out as the leading steel distributor all over India. Our decades of experience, in-depth industry knowledge, and customer-first approach make us the preferred choice for all your steel requirements of various brands like SAIL, Tata Steel, JSW, Jindal, JSPL, etc. We proudly deliver PAN India, ensuring timely and reliable supply wherever you are.

📞 Call us now to get a quote!

📍 Location: Raipur (CG)

📞Phone: 07712292080 | 07415009930 | 07415009931

✉️Email: sales@banketrade.in | steel@banketrade.in

🌐Website: www.banketrade.in 🌐Blog Site– https://blog.banketrade.in/

Stay Connected with Us on

Read More