At Banke Tradecom Services Pvt Ltd (BTS), we know how crucial it is to select the right type of steel for your project. The two most common types, Hot Rolled Steel and Cold Rolled Steel, serve different purposes. Understanding their differences of Hot Rolled Steel vs Cold Rolled Steel will help you make informed decisions that balance cost, quality, and application.

What is Hot Rolled Steel ?

Hot rolled steel is processed at extremely high temperatures, making it easier to shape and form into large sections. This method makes it ideal for large-scale structural projects that prioritize strength and durability over precise finishes.

Uses of Hot Rolled Steel

- Construction beams and frames: Perfect for I-beams, H-beams, and columns used in buildings and bridges.

- Railway tracks: Hot rolled steel provides the strength needed to withstand the stress of heavy trains.

- Heavy-duty machinery: Ideal for parts that don’t require fine finishing but need high durability, such as industrial equipment.

Examples of Hot Rolled Steel Applications

- Bridges: Used for beams and structural support.

- Shipbuilding: Bulkheads and structural sections in ships.

- Steel frames: Construction of skyscrapers and large buildings.

Benefits of Hot Rolled Steel

- Affordable: Cost-effective for large projects requiring significant amounts of steel.

- Versatile: Easy to shape and weld, suitable for large, structural components.

- Durable: Designed for high-stress, heavy-load applications.

What is Cold Rolled Steel?

Cold rolled steel is processed at room temperature, resulting in a smooth finish and tighter dimensional tolerances. This makes it ideal for applications where appearance, accuracy, and strength are critical.

Uses of Cold Rolled Steel

- Automotive components: Cold rolled steel is commonly used for body panels and frames, requiring precise dimensions and a smooth finish.

- Home appliances: Fridges, washing machines, and other appliances benefit from cold rolled steel’s refined appearance.

- Precision tools and hardware: Used for bolts, nuts, and precision-cut parts that require exact measurements.

Examples of Cold Rolled Steel Applications

- Automobile industry: Car doors, chassis, and exterior parts.

- Furniture: Office desks and filing cabinets.

- Electrical appliances: Covers and panels for electronics and home appliances.

Benefits of Cold Rolled Steel

- Higher strength: Offers greater tensile strength than hot rolled steel.

- Smooth finish: Ideal for exposed parts where appearance matters.

- Precision: Perfect for detailed projects requiring exact dimensions and minimal variation.

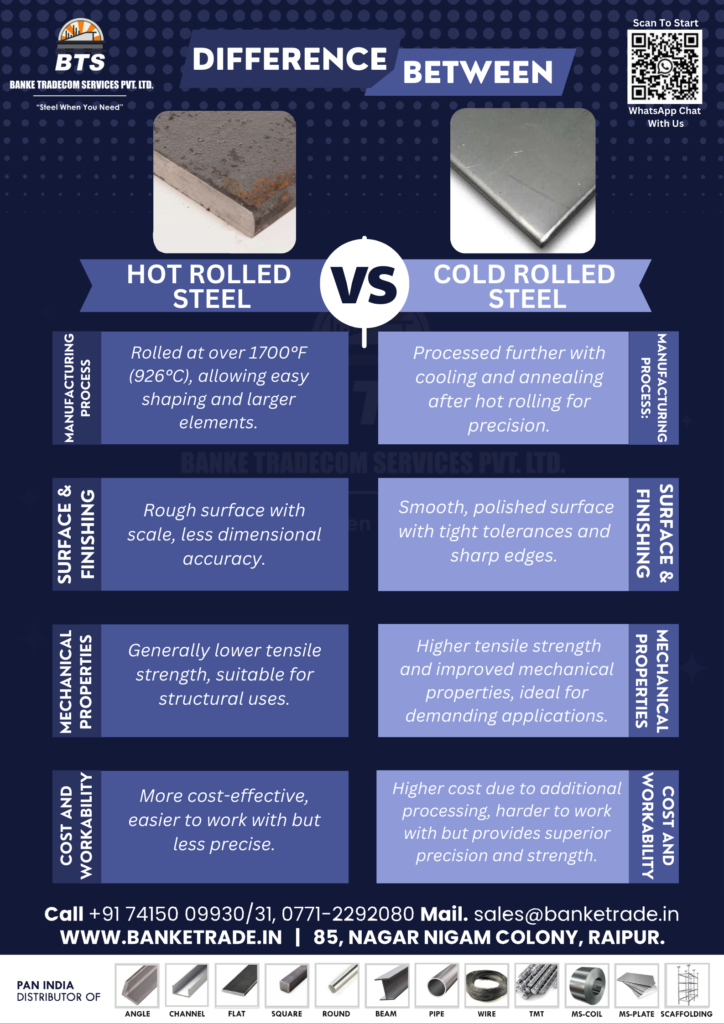

Differences Between :Hot Rolled Steel vs Cold Rolled Steel

| Feature | Hot Rolled Steel | Cold Rolled Steel |

|---|---|---|

| Forming Process | Processed at high temperatures, making it easier to shape. | Formed at room temperature for precision and smooth finish. |

| Surface Finish | Rough finish, typically used for hidden or structural parts. | Smooth and polished, ideal for exposed applications. |

| Strength | Good for strength, but lower than cold rolled steel. | Higher strength due to more refined processing. |

| Cost | Budget-friendly, great for large-scale use. | Slightly more expensive, suitable for precision projects. |

| Applications | Best for beams, frames, and large structures. | Perfect for automotive parts, appliances, and precision tools. |

About us –

At BTS, we stand out as the leading steel supplier in Maharashtra, Madhya Pradesh, Chhattisgarh and all over India. Our decades of experience, in-depth industry knowledge, and customer-first approach make us the preferred choice for all your steel requirements of various brands like SAIL, Tata Steel, JSW, Jindal, JSPL, etc. We proudly deliver PAN India, ensuring timely and reliable supply wherever you are.

📞 Call us now to get a quote!

📍 Location: Raipur (CG)

📞Phone: 07712292080 | 07415009930 | 07415009931

✉️Email: sales@banketrade.in | steel@banketrade.in

🌐Website: www.banketrade.in 🌐Blog Site– https://blog.banketrade.in/

Stay Connected with Us on