When it comes to construction, selecting the right TMT (Thermo-Mechanically Treated) bars or How to Choose TMT is essential for ensuring the strength, safety, and longevity of your structure. At Banke Tradecom Services Pvt Ltd (BTS), we are committed to helping you make the best choice based on your specific project needs.

What Are TMT Bars?

Full form of TMT is Thermo-Mechanically Treated. TMT bars are steel reinforcement bars that are thermally treated to improve their strength and durability. These bars undergo a process of quenching, self-tempering, and atmospheric cooling, which gives them their unique properties like high tensile strength, flexibility, and corrosion resistance. TMT bars are critical in construction, offering support to structures like buildings, bridges, and other heavy-duty frameworks.

Advantages

- High Strength: TMT bars offer superior tensile strength, making them ideal for construction in earthquake-prone areas.

- Corrosion Resistance: These bars have a tough outer surface that resists corrosion, ensuring durability in moist and coastal environments.

- Earthquake Resistance: The high ductility of TMT bars allows them to absorb shock waves, making them perfect for structures in seismic zones.

- Fire Resistance: TMT bars can withstand high temperatures, providing additional safety to buildings during fire incidents.

- Flexibility: TMT bars can be bent easily without cracking, allowing them to adapt to different shapes and construction requirements.

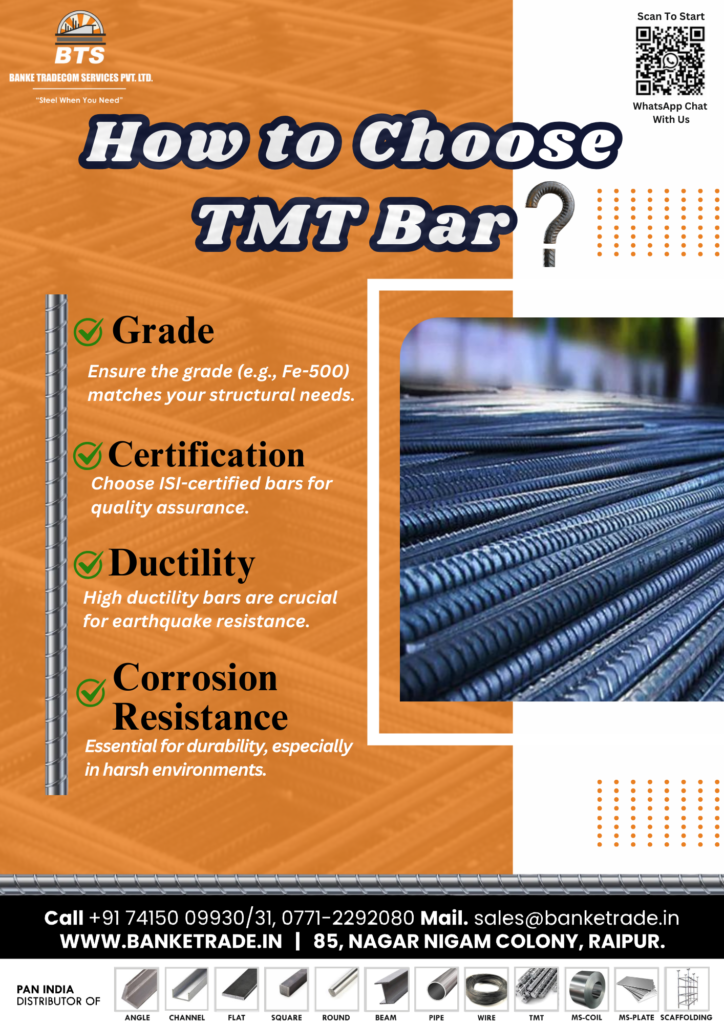

How to Choose the TMT Bars

1. Consider the Grade

TMT bars are available in various grades like Fe-500, Fe-550, and Fe-600, which indicate their strength.

- Fe-500 is ideal for residential buildings where moderate strength is required.

- Fe-600 is best suited for heavy-duty structures such as bridges, industrial complexes, and high-rises.

At BTS, we offer a wide range of TMT grades to ensure you get the right balance of strength and flexibility for your specific project.

2. Focus on Corrosion Resistance

In areas prone to moisture or coastal climates, opt for TMT bars with high corrosion resistance. This feature is essential to ensure that the steel does not rust over time, compromising the structure’s safety. At BTS, we provide corrosion-resistant TMT bars designed to withstand even the harshest environmental conditions.

3. Check for Flexibility and Ductility

High-quality TMT bars should be able to bend without breaking, ensuring flexibility during construction. This is particularly important in regions prone to earthquakes or natural forces. At BTS, our TMT bars are engineered for maximum ductility, ensuring your structure’s safety even under extreme conditions.

4. Trust the Certification

Always choose TMT bars that are BIS (Bureau of Indian Standards) certified. Certification guarantees that the bars meet the required quality and safety standards. At BTS, we supply only BIS-certified TMT bars, ensuring that your project is built on a foundation of reliability and quality.

About us –

At BTS, we stand out as the leading steel supplier in CG. Our decades of experience, in-depth industry knowledge, and customer-first approach make us the preferred choice for all your steel requirements of various brands like SAIL, Tata Steel, JSW, Jindal, JSPL, etc. We proudly deliver PAN India, ensuring timely and reliable supply wherever you are.

📞 Call us now to get a quote!

📍 Location: Raipur (CG)

📞 Phone: 07712292080 | 07415009930 | 07415009931

✉️ Email: sales@banketrade.in | steel@banketrade.in

🌐 Website: www.banketrade.in

Stay Connected with Us on

Read More